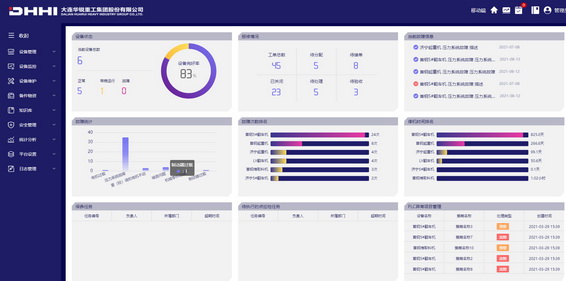

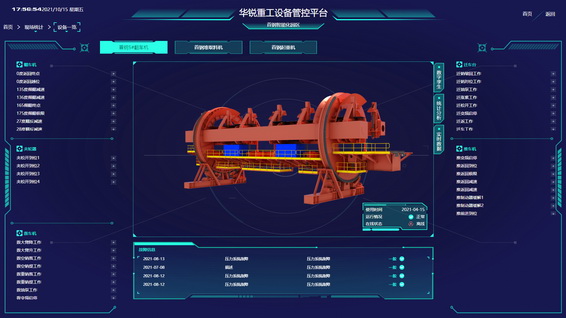

Based on data analysis, DHHI developed a remote intelligent operation and maintenance platform according to product performance and technical characteristics. It is integrated with currently-prevailing advanced technologies such as fault diagnosis technology, sensor detection technology, digital twin technology, data analysis and data mining algorithms, cloud computing, etc. to realize the functions of fault location, pushing of maintenance plan and suggestion, etc., which has been successfully applied to coke oven machinery, stackers and reclaimers, cranes, continuous ship unloaders, sub-merged arc furnaces, etc.

The functions of fault location, pushing of maintenance plan and suggestion, etc. are realized on the basis of data analysis. It is integrated with currently-prevailing advanced technologies such as fault diagnosis technology, sensor detection technology, digital twin technology, data analysis and data mining algorithms, cloud computing, etc. It copes with the current extensive operation and maintenance status of heavy machinery to achieve the goals of scientific operation, appropriate spot inspection, precise maintenance, reducing maintenance costs, shortening downtime and extending the overall life of equipment.

CN

CN